Top 5 challenges in front of manufacturing industry

In today’s world, to remain competitive in manufacturing, the manufacturers have to shift production to the higher values, advanced technology support and to offer new product-as-a-service model. As per a Forbes report by 2020, 47% of all the products will be smart, connected and capable of providing product-as-a-service.

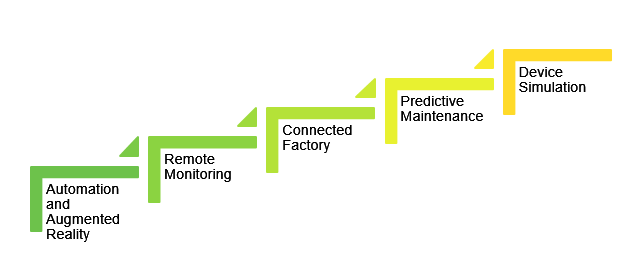

But there are pain areas as well that manufacturing industry has to face, below are some of the struggles the industry has faced in recent times,

- Shortage of Skilled Labor: As the industry is expecting technology fueled growth post Covid, when economies will start to rebound, as per an estimate there will be approx. 4.6 mn jobs will be available over the next decade while 2.4 mn will go unfulfilled.

- Intelligence from Machine: Automation, IoT, Robotics- with the increasing trend of technology in the industry, there us lot of data coming from the machines. The need of the hour is to analyze this data using Data Analytics and Machine Learning to help management to take better decisions.

- Maintenance: Every single day, manufacturing industry experiences breakdown and downtime, that impact significantly on the company growth. One of the true benefit of IoT, to analyze the historical data and predict the requirement of maintenance for a machine or equipment.

- System Usability: Another big issue in the manufacturing industry is usability of the machines and equipment, with device simulation the workforce can be trained using the technology as a savior for the industry.

Predictive Maintenance:

By default, most businesses rely on corrective maintenance. Parts are replaced as and when they fail, this causes factory to shut down that impacts the products manufacturing, thus the unhappy customers. At the next level, businesses practice preventive maintenance, where they determine the useful lifespan for a part, and maintain or replace it before a failure, this may lead to unnecessary maintenance of machines or equipment that was not still required, thus wastage of money.

Predictive Maintenance is to optimize the balance between corrective and preventative maintenance, by enabling just in time replacement of components.

Predictive Maintenance Benefits:

- This approach only replaces those components when they are close to a failure

- Cost savings and competitive advantages to business.

- End-to-End solution for a business scenario that predicts the point at which a failure is likely to occur

- Proactively optimizes maintenance and create automatic alerts and actions for remote diagnostics and maintenance requests.

Predictive Maintenance using Azure Serverless components: Reference Architecture

Devices: Devices can be connected to the cloud directly or indirectly. Directly, using IP-capable devices that can establish secure connections via the internet. Indirectly, devices connect via a field gateway. This enables aggregation and reduction of raw device data before transport to the backend, and local decision-making capability on the edge.

IoT Hub: Azure IoT Hub offers built-in high-scale secure connectivity, data and event ingestion, and bi-directional communication with devices including device management with command and control capabilities. Azure IoT Hub can securely and performantly connect millions of devices to the cloud, from a variety of devices and protocols.

Stream Analytics: For the large amount of the data that is being generated by the field devices on real time, to process these live stream of data and complex rules associated with them, Azure Stream Analytics is used.

Event Hub: The stream analytics generates event and sends it to the Event Hub, which triggers background jobs for further analysis.

Event Processor: Web Job is used to process the event data that is being received from Event Hub, to apply the Machine Learning algorithms, a portion of this data is used to train the ML model as well.

Storage: It can be divided into warm path and cold path stores. Warm path data is required to be available for reporting and visualization immediately from devices. Cold path data is stored for a longer term, and used for batch processing. We use Azure Cosmos DB for warm path storage and Azure Blob Storage for cold storage.

Dashboard and UI- Web App or Power BI can be used to create and show the dashboard to the end user that will be used by the end users to browse the data in the interactive manner like charts etc.

Machine Learning: It enables systems to learn from historical data and experiences and to act without being explicitly programmed. Scenarios such as predictive maintenance are enabled through ML. We use Azure Machine Learning for ML needs.

References:

https://www.machinemetrics.com/blog/the-impact-of-predictive-maintenance-on-manufacturing

https://azure.microsoft.com/en-in/industries/discrete-manufacturing/usecases/